- 产(chǎn)品简介

- 产(chǎn)品特点

- 产(chǎn)品规格

- 产(chǎn)品尺寸

- 资料下载

- Solid shaft with key

- Solid shaft without key (K1 - K4, starting at K5 on request)

- Solid shaft on both sides

- Hollow shaft with keyway

- Hollow shaft with shrink ring

Housing Designs

- Pitch circle diameter

- Round flange

- Foot + pitch circle diameter

- Foot + round flange

- Pitch circle diameter + torque arm bracket

- Foot + pitch circle diameter + torque arm bracket

Backlash

- Standard

- Class II

- Class I

Mounting Positions

- Any mounting position.

- You can find the explanation of the mounting positions and the respective quantities of lubricant in the document Quantity of lubricant for gear units ID 441871

Lubricants and Maintenance

- Mineral lubricant CLP ISO VG 220

- Option: Synthetic lubricant CLP HC ISO VG 220

Under normal operating conditions no lubricant change is required for gear unit size K1 to K4 (lubricated for life).

We recommend a change of lubricant for gear unit size K5 to K10 after approx. 10,000 hours of operation.

Paint Finish

Black RAL 9005

Motor Adapter MB

- Integrated static current brake.

- As single brake or - together with motor brake - as redundant braking system.

- Motor adapter for all common synchronous servo motors.

- Plug-in coupling for easy removal of the motor with braked axis in any position.

Enclosure Type

IP54, optional IP65

Electrical Connection

- Standard design with terminal box and integrated release monitoring.

- Optionally with connector, however not in conjunction with electrical monitoring.

Coil

- Coil connection 24 VDC

- Coil connection 104 VDC (Connection voltage 220 – 277 V, ± 5%, 50//60 Hz) with high-speed rectifier.

For details see Operating instructions Brake module MB ID 441846

Option Hand Release

With the hand release the brake can be released mechanically.

Recommendation Motor

EZ synchronous servo motors

For further information see Synchronous Servo Motors

|

Type |

Ratio |

Max. perm. acceleration torque [Nm] |

Weight [kg] |

Max. perm. input speed in cyclic operation [1/min] |

Backlash [arcmin] |

Torsional stiffness [Nm/arcmin] |

|

K102 |

4 – 18 |

93 – 135 |

17 |

4000 |

6 – 12 |

5.1 – 6.7 |

|

K202 |

4 – 28 |

146 – 220 |

25 – 30 |

4000 |

1.5 – 10 |

7.1 – 11 |

|

K302 |

4 – 46 |

146 – 385 |

30 – 35 |

3800 – 4000 |

1.5 – 10 |

9.2 – 16 |

|

K402 |

4 – 56 |

244 – 600 |

43 – 60 |

3000 – 4000 |

1.5 – 10 |

16 – 31 |

|

K513 |

7.3 – 97 |

521 – 1000 |

49 – 66 |

3000 – 4000 |

2 – 10 |

34 – 49 |

|

K613 |

7.3 – 95 |

615 – 1600 |

70 – 88 |

2900 – 4000 |

2 – 10 |

47 – 82 |

|

K713 |

7.6 – 99 |

1126 – 2600 |

104 – 116 |

2700 – 3800 |

2 – 10 |

68 – 125 |

|

K813 |

7.4 – 97 |

1523 – 4650 |

158 – 169 |

2600 – 3600 |

2 – 10 |

83 – 194 |

|

K913 |

13 – 95 |

2562 – 7700 |

284 |

2800 – 3000 |

5 – 10 |

197 – 373 |

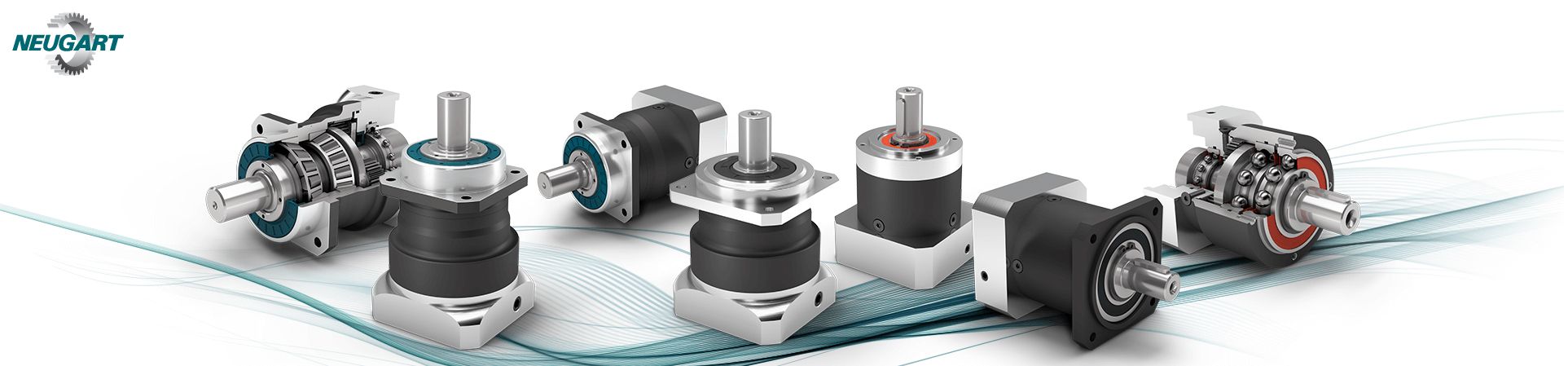

K Series

- 产(chǎn)品简介

- 产(chǎn)品特点

- 产(chǎn)品规格

- 产(chǎn)品尺寸

- 资料下载

- Solid shaft with key

- Solid shaft without key (K1 - K4, starting at K5 on request)

- Solid shaft on both sides

- Hollow shaft with keyway

- Hollow shaft with shrink ring

Housing Designs

- Pitch circle diameter

- Round flange

- Foot + pitch circle diameter

- Foot + round flange

- Pitch circle diameter + torque arm bracket

- Foot + pitch circle diameter + torque arm bracket

Backlash

- Standard

- Class II

- Class I

Mounting Positions

- Any mounting position.

- You can find the explanation of the mounting positions and the respective quantities of lubricant in the document Quantity of lubricant for gear units ID 441871

Lubricants and Maintenance

- Mineral lubricant CLP ISO VG 220

- Option: Synthetic lubricant CLP HC ISO VG 220

Under normal operating conditions no lubricant change is required for gear unit size K1 to K4 (lubricated for life).

We recommend a change of lubricant for gear unit size K5 to K10 after approx. 10,000 hours of operation.

Paint Finish

Black RAL 9005

Motor Adapter MB

- Integrated static current brake.

- As single brake or - together with motor brake - as redundant braking system.

- Motor adapter for all common synchronous servo motors.

- Plug-in coupling for easy removal of the motor with braked axis in any position.

Enclosure Type

IP54, optional IP65

Electrical Connection

- Standard design with terminal box and integrated release monitoring.

- Optionally with connector, however not in conjunction with electrical monitoring.

Coil

- Coil connection 24 VDC

- Coil connection 104 VDC (Connection voltage 220 – 277 V, ± 5%, 50//60 Hz) with high-speed rectifier.

For details see Operating instructions Brake module MB ID 441846

Option Hand Release

With the hand release the brake can be released mechanically.

Recommendation Motor

EZ synchronous servo motors

For further information see Synchronous Servo Motors

|

Type |

Ratio |

Max. perm. acceleration torque [Nm] |

Weight [kg] |

Max. perm. input speed in cyclic operation [1/min] |

Backlash [arcmin] |

Torsional stiffness [Nm/arcmin] |

|

K102 |

4 – 18 |

93 – 135 |

17 |

4000 |

6 – 12 |

5.1 – 6.7 |

|

K202 |

4 – 28 |

146 – 220 |

25 – 30 |

4000 |

1.5 – 10 |

7.1 – 11 |

|

K302 |

4 – 46 |

146 – 385 |

30 – 35 |

3800 – 4000 |

1.5 – 10 |

9.2 – 16 |

|

K402 |

4 – 56 |

244 – 600 |

43 – 60 |

3000 – 4000 |

1.5 – 10 |

16 – 31 |

|

K513 |

7.3 – 97 |

521 – 1000 |

49 – 66 |

3000 – 4000 |

2 – 10 |

34 – 49 |

|

K613 |

7.3 – 95 |

615 – 1600 |

70 – 88 |

2900 – 4000 |

2 – 10 |

47 – 82 |

|

K713 |

7.6 – 99 |

1126 – 2600 |

104 – 116 |

2700 – 3800 |

2 – 10 |

68 – 125 |

|

K813 |

7.4 – 97 |

1523 – 4650 |

158 – 169 |

2600 – 3600 |

2 – 10 |

83 – 194 |

|

K913 |

13 – 95 |

2562 – 7700 |

284 |

2800 – 3000 |

5 – 10 |

197 – 373 |