- 产(chǎn)品简介

- 产(chǎn)品特点

- 产(chǎn)品规格

- 产(chǎn)品尺寸

- 资料下载

- Gearing quality 5

- Case hardened and ground

- Optional concentricit≤ 10 µ

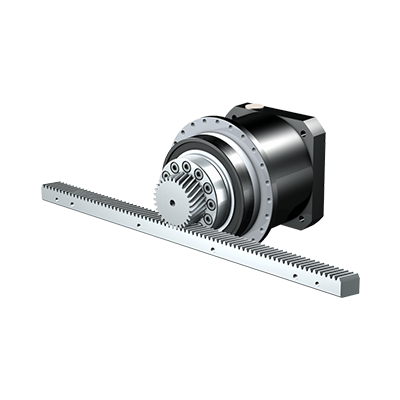

ZTR Output Pinion

ATLANTA Gear Racks

Our cooperation partner Atlanta offers matching gear racks for our products.

http://atlantagmbh.com/products/racks/

Mounting Positions

- Any mounting position.

Lubricants and Maintenance

Gear unit:

- Synthetic lubricant CLP HC ISO VG 150

- Lubricated for life

- Maintenance-free

Rack and pinion drive:

- Lubrication of the rack and pinion drive must be carried out by the customer.

- For this purpose, we recommend only the use of high quality synthetic oil based grease of NLGI grade 0.

Paint Finish

Black RAL 9005

Motor Adapter ME

- Universal motor mounting system for almost all synchronous servo motors.

- Option large (MEL) for large motors.

- Fast and secure motor mounting.

- Robust, balanced coupling.

- Thermal length compensation.

- Low mass inertia.

EasyAdapt

Option ServoStop

- Integrated in the motor adapter, electrically released spring-loaded brake.

- When the power is removed, in the event of a power failure or an emergency stop ServoStop will brake both drive and machine shaft safely and reliably.

- Zero-backlash plug-in coupling.

ServoStop Motor Adapter with Brake

Recommendation Motor

EZ synchronous servo motors

For further information see Synchronous Servo Motors

|

Type |

Module [mm] |

Teeth number |

Max. perm. acceleration feed force [kN] |

Max. feed velocity [m/s] |

Linear backlash [μm] |

|

ZTR2_PH421 |

2 |

12 – 16 |

5.8 – 6.7 |

0.8 – 2.2 |

11 – 15 |

|

ZTR2_PH422 |

2 |

12 – 16 |

5.8 – 6.7 |

0.11 – 0.72 |

11 – 15 |

|

ZTR2_PH521 |

2 |

12 – 23 |

6.7 – 10 |

0.8 – 3.2 |

11 – 21 |

|

ZTR3_PH521 |

3 |

12 – 14 |

9.3 – 10 |

1.2 – 2.9 |

17 – 19 |

|

ZTR2_PH522 |

2 |

12 – 23 |

6.7 – 10 |

0.09 – 0.96 |

11 – 21 |

|

ZTR3_PH522 |

3 |

12 – 14 |

9.3 – 10 |

0.14 – 0.88 |

17 – 19 |

|

ZTR2_PH721 |

2 |

12 – 23 |

6.7 – 15 |

0.67 – 2.6 |

11 – 21 |

|

ZTR3_PH721 |

3 |

16 – 19 |

17 – 19 |

1.3 – 3.2 |

22 – 26 |

|

ZTR4_PH721 |

4 |

12 |

19 |

1.3 – 2.7 |

22 |

|

ZTR2_PH722 |

2 |

12 – 23 |

6.7 – 15 |

0.09 – 0.8 |

11 – 21 |

|

ZTR3_PH722 |

3 |

16 – 19 |

17 – 19 |

0.17 – 0.99 |

22 – 26 |

|

ZTR4_PH722 |

4 |

12 |

19 |

0.17 – 0.83 |

22 |

|

ZTR3_PH821 |

3 |

19 – 32 |

21 – 25 |

1.3 – 4.7 |

26 – 44 |

|

ZTR4_PH821 |

4 |

17 – 20 |

28 – 35 |

1.5 – 3.9 |

31 – 37 |

|

ZTR5_PH821 |

5 |

12 – 18 |

25 – 34 |

1.3 – 4.4 |

28 – 42 |

|

ZTR6_PH821 |

6 |

15 |

25 – 30 |

2 – 4.4 |

42 |

|

ZTR3_PH822 |

3 |

19 – 32 |

21 – 25 |

0.19 – 1.5 |

26 – 44 |

|

ZTR4_PH822 |

4 |

17 – 20 |

28 – 35 |

0.23 – 1.3 |

31 – 37 |

|

ZTR5_PH822 |

5 |

12 – 18 |

25 – 34 |

0.2 – 1.4 |

28 – 42 |

|

ZTR6_PH822 |

6 |

15 |

25 – 30 |

0.3 – 1.4 |

42 |

|

ZTR5_PH932 |

5 |

18 – 19 |

63 – 67 |

0.38 – 1.3 |

42 – 44 |

|

ZTR6_PH932 |

6 |

16 |

56 |

0.4 – 1.3 |

44 |

|

ZTR6_PH1032 |

6 |

16 |

56 |

0.4 – 0.89 |

44 |

|

ZTR8_PH1032 |

8 |

12 |

60 |

0.4 – 0.89 |

44 |

ZTRPH Series

- 产(chǎn)品简介

- 产(chǎn)品特点

- 产(chǎn)品规格

- 产(chǎn)品尺寸

- 资料下载

- Gearing quality 5

- Case hardened and ground

- Optional concentricit≤ 10 µ

ZTR Output Pinion

ATLANTA Gear Racks

Our cooperation partner Atlanta offers matching gear racks for our products.

http://atlantagmbh.com/products/racks/

Mounting Positions

- Any mounting position.

Lubricants and Maintenance

Gear unit:

- Synthetic lubricant CLP HC ISO VG 150

- Lubricated for life

- Maintenance-free

Rack and pinion drive:

- Lubrication of the rack and pinion drive must be carried out by the customer.

- For this purpose, we recommend only the use of high quality synthetic oil based grease of NLGI grade 0.

Paint Finish

Black RAL 9005

Motor Adapter ME

- Universal motor mounting system for almost all synchronous servo motors.

- Option large (MEL) for large motors.

- Fast and secure motor mounting.

- Robust, balanced coupling.

- Thermal length compensation.

- Low mass inertia.

EasyAdapt

Option ServoStop

- Integrated in the motor adapter, electrically released spring-loaded brake.

- When the power is removed, in the event of a power failure or an emergency stop ServoStop will brake both drive and machine shaft safely and reliably.

- Zero-backlash plug-in coupling.

ServoStop Motor Adapter with Brake

Recommendation Motor

EZ synchronous servo motors

For further information see Synchronous Servo Motors

|

Type |

Module [mm] |

Teeth number |

Max. perm. acceleration feed force [kN] |

Max. feed velocity [m/s] |

Linear backlash [μm] |

|

ZTR2_PH421 |

2 |

12 – 16 |

5.8 – 6.7 |

0.8 – 2.2 |

11 – 15 |

|

ZTR2_PH422 |

2 |

12 – 16 |

5.8 – 6.7 |

0.11 – 0.72 |

11 – 15 |

|

ZTR2_PH521 |

2 |

12 – 23 |

6.7 – 10 |

0.8 – 3.2 |

11 – 21 |

|

ZTR3_PH521 |

3 |

12 – 14 |

9.3 – 10 |

1.2 – 2.9 |

17 – 19 |

|

ZTR2_PH522 |

2 |

12 – 23 |

6.7 – 10 |

0.09 – 0.96 |

11 – 21 |

|

ZTR3_PH522 |

3 |

12 – 14 |

9.3 – 10 |

0.14 – 0.88 |

17 – 19 |

|

ZTR2_PH721 |

2 |

12 – 23 |

6.7 – 15 |

0.67 – 2.6 |

11 – 21 |

|

ZTR3_PH721 |

3 |

16 – 19 |

17 – 19 |

1.3 – 3.2 |

22 – 26 |

|

ZTR4_PH721 |

4 |

12 |

19 |

1.3 – 2.7 |

22 |

|

ZTR2_PH722 |

2 |

12 – 23 |

6.7 – 15 |

0.09 – 0.8 |

11 – 21 |

|

ZTR3_PH722 |

3 |

16 – 19 |

17 – 19 |

0.17 – 0.99 |

22 – 26 |

|

ZTR4_PH722 |

4 |

12 |

19 |

0.17 – 0.83 |

22 |

|

ZTR3_PH821 |

3 |

19 – 32 |

21 – 25 |

1.3 – 4.7 |

26 – 44 |

|

ZTR4_PH821 |

4 |

17 – 20 |

28 – 35 |

1.5 – 3.9 |

31 – 37 |

|

ZTR5_PH821 |

5 |

12 – 18 |

25 – 34 |

1.3 – 4.4 |

28 – 42 |

|

ZTR6_PH821 |

6 |

15 |

25 – 30 |

2 – 4.4 |

42 |

|

ZTR3_PH822 |

3 |

19 – 32 |

21 – 25 |

0.19 – 1.5 |

26 – 44 |

|

ZTR4_PH822 |

4 |

17 – 20 |

28 – 35 |

0.23 – 1.3 |

31 – 37 |

|

ZTR5_PH822 |

5 |

12 – 18 |

25 – 34 |

0.2 – 1.4 |

28 – 42 |

|

ZTR6_PH822 |

6 |

15 |

25 – 30 |

0.3 – 1.4 |

42 |

|

ZTR5_PH932 |

5 |

18 – 19 |

63 – 67 |

0.38 – 1.3 |

42 – 44 |

|

ZTR6_PH932 |

6 |

16 |

56 |

0.4 – 1.3 |

44 |

|

ZTR6_PH1032 |

6 |

16 |

56 |

0.4 – 0.89 |

44 |

|

ZTR8_PH1032 |

8 |

12 |

60 |

0.4 – 0.89 |

44 |